WORKS

FY2024

| Project Name | Research and development on control design of redundant electric fuel metering system |

|---|---|

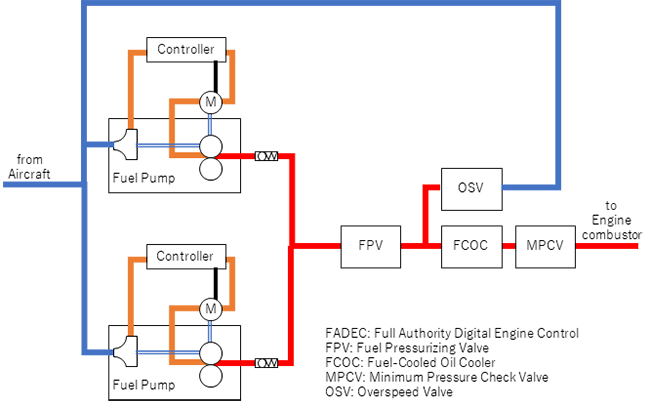

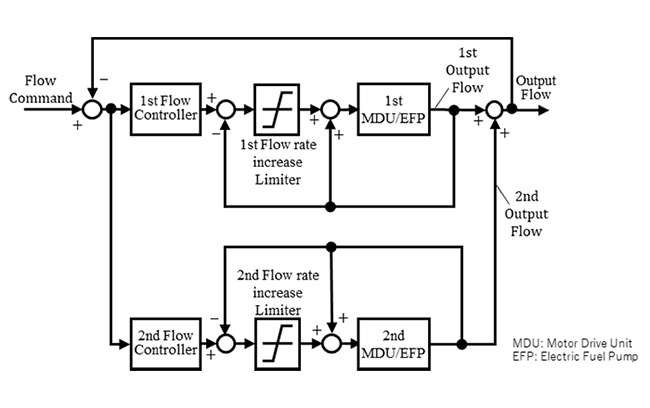

| Progress status and Results summary | A redundant electric fuel metering system has been devised as research and development for the electrification of aircraft fuel systems. In this system, the fuel pump is directly driven by an electric motor, and the electric fuel pumps are configured in parallel and redundantly to improve reliability [1]. We study the redundant control function of this system and aim to build a basic theory for application technology of high-performance electric motors. In addition, we also aim to evaluate and verify fault tolerance performance as a redundant configuration. So far, we have developed an optimal control design method using a nonlinear model of the system [2] and model-based design for fault-tolerant control. Currently, continuing from last year, we are constructing and verifying a mathematical model for internal pump leakage with the aim of improving flow control accuracy. We have also published a paper on model-based fault-tolerant control design [3]. |

| Results | [1] N. Morioka, H. Oyori, N. Seki, T. Fukuda et al.: “Thermal management system for the MEE and Engine embedded electric machine” ,ASME GT2018-76356,(2018)

[2] Y. Yamamoto, Y. Shibuya, H. Oyori, and M. Muraoka.: “Control Design under Limitation of Current for Electric Fuel Metering System with Redundancy on Aircraft Electrification”, SAE International Journal of Advances and Current Practices in Mobility, Volume 5, Issue 5, pp.1841-1848,(2023) [3] Yamamoto, Y., Muraoka, M., Sugawara, H., Umeki, Y. et al., “Model-Based Fault Tolerant Design of Redundant Electric Fuel Metering System for Aircraft,” J. Jpn. Soc. Aeronaut. Space Sci. 72(4):117-129, 2024, (in Japanese) |

Fig. 1?Redundant Electric Fuel Metering System(EFMS) [1]

Fig. 2?The nonlinear Redundant EFMS model [2]

Fig. 3 Overview of fault-tolerant models for each failure mode [3]

FY2023

| Project Name | NEDO Research and Development Project for Advanced Aircraft Systems toward Practical Application |

|---|---|

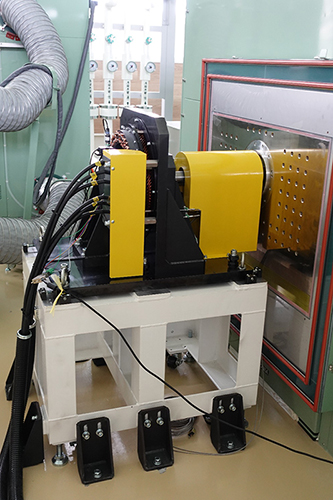

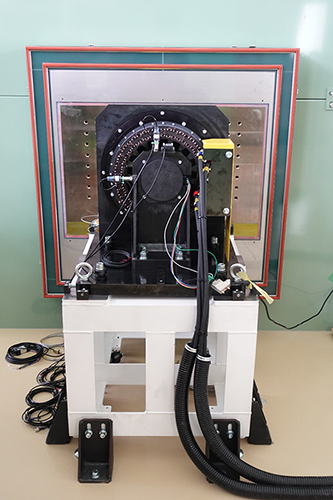

| Progress status and Results summary | As a technological innovation for reducing CO2 emissions from aircraft, the world's first 1 MW-class electric motor that can be installed behind a jet engine was developed in cooperation with domestic companies to optimize the energy management of the entire aircraft system including the engine. This motor was evaluated at Evaluation Laboratory for Next Generation Motors of Joint Research Center for Electrification Architecture in Akita University, and it was confirmed that the expected performance could be obtained, and the motor could cope with the changes in speed and power output when directly connected to the engine shaft. This research was conducted under the "Research and Development Project for Advanced Aircraft Systems toward Practical Application/ Research and Development for Next Generation Electric Propulsion System / Electric Hybrid System" commissioned by the New Energy and Industrial Technology Development Organization (NEDO) under the "Practical Application of Advanced Aircraft Systems Project. |

| Results | IHI Press Release (January 12, 2024) NEDO Project Introduction |

Fig. 1 Electric motor - Installation on test equipment

| Project Name | Practical Application Project for Advanced Aircraft Systems / Research and Development of Next Generation Electric Propulsion System / Electric Hybrid System - Research on Heat and Air Management Unit |

|---|---|

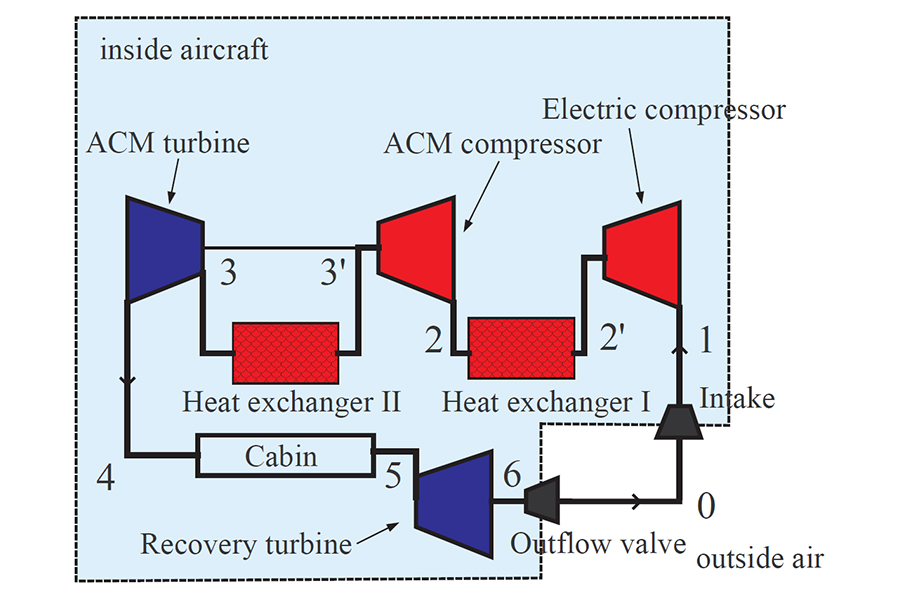

| Progress status and Results summary | The energy recovery rate of an electric ECS system was experimentally determined by reproducing the in-flight conditions of an aircraft in cruise flight using the demonstration test rig at the Joint Research Center for Electric Architecture. The temperature and pressure conditions were reproduced at four different altitudes from 26,000 to 35,000 feet to determine the energy that could be recovered by the recovery turbine. It was found that over 40% of the energy required to operate the electric compressor could be recovered. This article is based on results obtained from a project, JPNP15005, commissioned by the New Energy and Industrial Technology Development Organization (NEDO). |

| Results | 1、Adachi, T., Takahashi, K., Ishii, S., Seki, N., Oyori, H., Thermodynamic analysis of a new electric environmental control system with energy recovery turbine, Journal of Thermal Science and Technology, 2024, 19(1), 23-00295 2、Amano, Y., ,Saito, H., Adachi,T., Optimal Operating Conditions for an Electric ECS in Ground Parking Status, 20th international conference on flow dynamics, November 6-8, Sendai, Miyagi, Japan. |

Fig. 1 Overall view of experimental apparatus

Fig. 2 Flowchart

| Project Name | Research and development on control design of redundant electric fuel metering system |

|---|---|

| Progress status and Results summary | A redundant electric fuel metering system has been devised as a research and development for the electrification of aircraft fuel systems. In this system, the fuel pump is directly driven by an electric motor, and the electric fuel pumps are configured in parallel and redundantly to improve reliability [1]. We study the redundant control function of this system and aim to build a basic theory for application technology of high-performance electric motors. In addition, we also aim to evaluate and verify fault tolerance performance as a redundant configuration. So far, we have developed an optimal control design method using a nonlinear model of the system [2] and model-based design for fault-tolerant control. Currently, with the aim of improving flow rate control accuracy, we are studying the construction of a mathematical model for internal pump leaks and acquiring the data necessary to construct the mathematical model. |

| Results | [1] N. Morioka, H. Oyori, N. Seki, T. Fukuda et al.: “Thermal management system for the MEE and Engine embedded electric machine” ,ASME GT2018-76356,(2018) [2] Y. Yamamoto, Y. Shibuya, H. Oyori, and M. Muraoka.: “Control Design under Limitation of Current for Electric Fuel Metering System with Redundancy on Aircraft Electrification”, SAE International Journal of Advances and Current Practices in Mobility, Volume 5, Issue 5, pp.1841-1848,(2023) |

Fig. 1? Redundant Electric Fuel Metering System(EFMS) [1]

Fig. 2? The nonlinear Redundant EFMS model[2]

Fig. 3 Pump structure and internal leaks

FY2022

| Project Name | Characterization of a prototype Halbach motor |

|---|---|

| Progress status and Results summary | In the ‘Creating Industry through Research and Development of Compact and Lightweight Electrification Systems’ project, which Akita Prefectural Government applied for with the participation of Akita University, was approved by the Cabinet Office, the characteristics of the prototype Halbach motor (maximum output 250 kW) were tested. |

| Results | See below Succeeded in developing a prototype high-power aircraft propulsion motor (Halbach motor). |

※Halbach motor(Photo from the side, with cover)

※Halbach motor(Front view photo, no cover)

| Project Name | Research and development on control design of redundant electric fuel metering system |

|---|---|

| Progress status and Results summary | A redundant electric fuel metering system has been devised as a research and development for the electrification of aircraft fuel systems. In this system, the fuel pump is directly driven by an electric motor, and the electric fuel pumps are configured in parallel and redundantly to improve reliability [Result 1]. We study the redundant control function of this system and aim to build a basic theory for application technology of high-performance electric motors. In addition, we also aim to evaluate and verify fault tolerance performance as a redundant configuration. So far, to build a nonlinear model of the system, we have devised a method of modeling the nonlinear characteristics by adding a limiter for the flow rate increase to the linear model obtained by system identification, and We confirmed that the simulation results agree well with the experimental results [Result 2]. Currently, we are working on the fault-tolerant control design of the system with the optimized control system and the construction of an estimation model for improving the control accuracy. |

| Results | [Result 1] N. Morioka, H. Oyori, N. Seki, T. Fukuda et al.: “Thermal management system for the MEE and Engine embedded electric machine” ,ASME GT2018-76356,(2018) [Result 2] Y. Yamamoto, Y. Shibuya, H. Oyori, and M. Muraoka.: “Control Design under Limitation of Motor Current for Electric Fuel Metering System with Redundancy on Aircraft Electrification”,SAE 2023-01-0987,(2023) |

※ Redundant Electric Fuel Metering System(EFMS)

(Quoted from Result1)

※ The nonlinear Redundant EFMS model with the flow command increment limiter(Quoted from Result 2)

| Project Name | The study of thermal air management system for aircraft air conditioning system |

|---|---|

| Progress status and Results summary | In recent years, the trend for Net Zero in the aviation industry has accelerated, and many R&D efforts are conducted to reduce fuel consumption. In aircraft systems, the air conditioning system is a major energy consumer, and the energy is the compressed air produced by the jet engine. However, using that energy for the air conditioning system reduces the efficiency of the jet engine. We are developing a thermal air management system which improves the efficiency by using an electric turbocharger integrated with an electric compressor and a turbine. The electric compressor supplies compressed air instead of a jet engine, and the turbine recovers the energy of the compressed air and the heat from passengers and avionics. In FY2022, we built a sub-scale ground test rig with a reduced flow rate to confirm the system feasibility and demonstrated tests simulating cruise conditions. Currently, we are evaluating the test results and considering the test conditions for an operational feasibility study. This article is based on results obtained from a project, JPNP15005, commissioned by the New Energy and Industrial Technology Development Organization (NEDO). |

| Results | None |

※Conceptual diagram of the thermal air management experimental system

※The thermal air management experimental system